India's Battery Market Growth: Leadership Through Strategic Interventions, Not Scale

- Shivam Mishra

- Jul 31, 2025

- 5 min read

Updated: Aug 15, 2025

India battery market growth will increasingly depend on strategic leadership and innovation in technology, policy, and supply chain design.

Insights from Blue Lava Strategy Consultants

India’s battery market is valued at $8.5–9 billion by mid‑2025 and is expected to grow 10–12% annually through 2032. This is a defining inflection point. Electric mobility, renewable energy storage, and consumer electronics demand are converging to create an enormous domestic and global opportunity.

The choice ahead is clear: compete on price like China, or lead through design, resilience, and innovation that set new global standards.

Global benchmarks underline the stakes:

China: Controls over 75% of global cell and precursor material supply.

U.S.: Has invested more than $50 billion in securing supply chains and redundancy.

EU: Enforces lifecycle circularity with digital Battery IDs and rigorous recycling mandates.

India’s edge will come from Economies of Scope: modular design, universal traceability, circular resource use, and grid‑edge innovation, not replication of mass scale.

These global benchmarks and strategic choices set the stage for the six critical levers that will define India’s unique path to battery leadership.

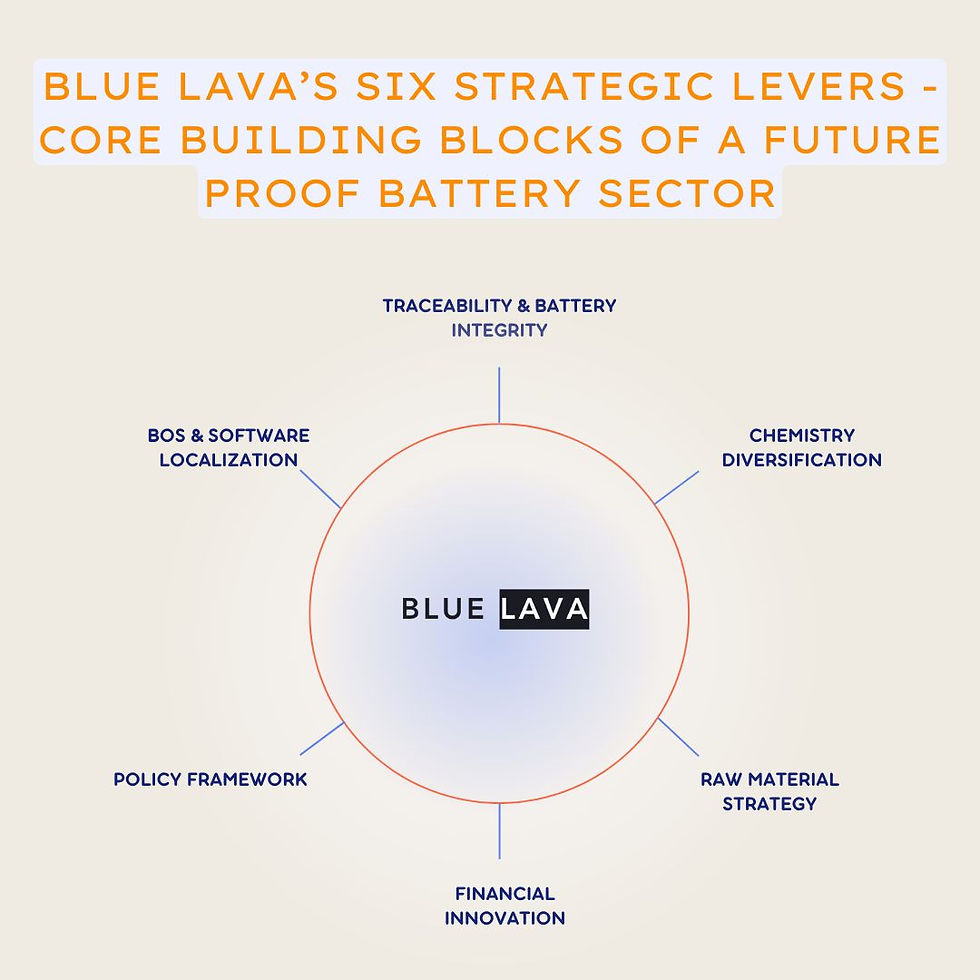

Six Strategic Levers for India‑First Battery Leadership

For India to secure a differentiated position in the global battery race, it must focus on a set of decisive levers that work in concert across technology, policy, finance and resource management. These levers are interconnected pillars designed to build scale with resilience, reduce import vulnerability, and capture high‑value opportunities across the value chain. Together, they form the backbone of a design‑led execution strategy capable of turning vision into leadership.

1. Diversify Chemistries: Reduce dependency and lead in non‑lithium solutions.

By reducing reliance on lithium and deploying alternative chemistries, India can cushion itself against price volatility and geopolitical supply shocks while building leadership in emerging global markets. India currently relies on imports for over 80% of its lithium, cobalt, and nickel. Pilots with Tata Power–LiNa Energy have demonstrated a 50% cost advantage for sodium‑ion over lithium‑ion, with national rollout targeted for 2027–28. Zinc‑air and other alternatives are under development at DRDO, IITs, and JNCASR. Impact: Potential to offset 15–20% of imports by 2030, reduce supply risk, and open new export segments.

2. Localize BoS and Software: Capture high‑value, high‑control segments.

Localizing Balance‑of‑System (BoS) hardware and control software ensures India owns the “intelligence layer” of energy storage, adding both profitability and strategic control. BoS components, battery management systems (BMS), and energy management systems (EMS) account for more than half of total system cost. India’s Production Linked Incentive (PLI) schemes and 2024 ESS/BoS policy upgrades are attracting both domestic and foreign investment in homegrown solutions. Impact: Reduce system costs by 15–20%, create proprietary intellectual property, and position India as a global exporter in a $35–50 billion market by 2030.

3. Mandate Traceability and Integrity: Build trust, safety, and resale value.

Traceability converts batteries from opaque hardware into verified, bankable assets in a trust‑driven energy market. The “Battery Aadhaar” initiative will give each battery above 1MWh a unique digital ID to track its lifecycle. Pilots with Tata Elxsi, CSTEP, and AEEE are proving its potential to prevent second‑hand fraud, mitigate safety risks, and enable second‑life usage. Impact: Increase recycling recovery rates by 20–30%, boost investor confidence, and expand resale opportunities.

4. Strengthen Policy Frameworks: Ensure central–state alignment for faster scale‑up. Aligning national and state energy storage policies will ensure ambition translates into financed, executable projects without bottlenecks. The National ESS Framework (2023) targets 336 GWh capacity by 2030 with supportive measures such as interstate transmission waivers and state mandates like Rajasthan’s 125 GW RE+storage program. Impact: Convert policy ambition into bankable projects more rapidly, attract large‑scale foreign investment, and reduce execution delays.

5. Innovate Financing Models: Enable access for all market participants.

Financial inclusion in the battery sector accelerates adoption, deepens local supply chains, and broadens the innovation base. Battery‑plus‑renewable tariffs now range between ₹3.10 and ₹3.50 per kWh, with BESS capex below $55/kWh. Mechanisms such as Viability Gap Funding (VGF), blended finance, and SECI’s revenue stacking have lowered costs, yet MSMEs still face barriers to funding. Impact: Unlock adoption across all scales, de‑risk innovation, and strengthen regional manufacturing ecosystems.

6. Secure Raw Material Sovereignty: Reduce supply vulnerability.

Securing resources is not only about safeguarding supply but also about defining India’s role in the global clean energy economy. Through KABIL and partnerships with Australia, Argentina, Chile, and Bolivia (including the Altmin–YLB C‑LFP project), India is strengthening upstream resilience. Urban mining initiatives by Gravita and Lohum are expanding under new Extended Producer Responsibility (EPR) mandates. Impact: Achieve 10–15% indigenous sourcing by 2030, insulate against commodity shocks, and contribute to a domestic circular economy.

Together, these strategic levers form a fully integrated pathway from upstream resource acquisition to end‑of‑life recycling, placing India on track for a resilient and globally competitive battery industry.

What’s at Stake if We Delay?

India’s pilots are promising, but slow execution will hand competitive advantage to faster‑moving rivals. This is more than a funding issue — the loss is strategic and long‑term:

Market share erosion: Others move faster to capture export markets.

Loss of global influence: Dependence on external standards and technologies.

Talent drain: Skilled professionals migrate to stronger ecosystems abroad.

Reduced control: Prolonged reliance on overseas supply chains.

Opportunity cost is real — every delay now shifts value and influence abroad. Acting decisively now will determine whether India sets the rules of the game or plays by others’ terms.

Blue Lava’s Priority Recommendations

Addressing these risks demands execution discipline and collaboration between industry, government, and research partners. Immediate, high‑impact actions include:

Launch a dual‑chemistry roadmap to scale lithium‑ion while accelerating sodium‑ion and zinc‑air pilots.

Mandate universal battery IDs for all systems above 1MWh capacity.

Expand PLI incentives to include software, analytics, and EMS/BMS solutions.

Implement a unified national circular economy and recycling policy.

Create pooled guarantee funds and small‑ticket blended financing to enable MSME participation.

Secure mineral contracts alongside investments in domestic refining.

Close the talent gap through targeted programs in BMS, EMS, and power systems.

These measures will accelerate capacity growth, reduce dependency risks, and put India’s battery sector on a path to sustainable global competitiveness.

The Path Forward

India’s leadership in energy storage will not be won on volume alone. It will come from designing flexible, circular, and high‑value systems that meet diverse needs across mobility, grid storage, and industry.

Execution must be coordinated, deliberate, and anchored in strategic design. The question is not whether India can lead, but whether it will act quickly enough to secure that role. The time to act is now: to turn strategic design into decisive leadership that shapes the future of global energy.

References:

Core Market Data & Forecasts

IMARC Group. (2024). India Battery Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2033.

TechSci Research. (2024). India Battery Market Forecast and Opportunities, 2030.

Research & Markets. (2024). India Automotive Battery Market 2024-2029.

IESA India Energy Storage Alliance. (2025). India Energy Storage Market Overview.

Technology, Chemistry, and Innovation

Times of India. (2025, June). Altmin-YLB MoU: India, Bolivia to cooperate on cathode tech, 10 GWh plant.

Tata Power & LiNa Energy (2025). Sodium-ion Battery BESS Pilot Report, UK/India ITES-JETSI.

CSTEP (2025). Fast-Charging Sodium-Ion Battery Prototypes for Indian Market.

AEEE (2025). Traceability Pilot Data for Grid Storage.

Policy, Regulation, and Government Data

Ministry of New & Renewable Energy (MNRE), Govt. of India (2022–2025). Battery Waste Management Rules & Updates.

ESS National Framework, Ministry of Power (2024).

SECI (2025). India’s Battery Storage Tenders and Tariff Reports.

Industry and Pilot Reports

JETSI Consortium (2025). India-UK Sodium-ion Pilot: Outcomes and Cost Summary.

ET Government. (2025). Battery Traceability Pilots and Policy Summaries.

SPML Infra. (2025). White Papers on Battery Infrastructure.

Power Ministry, GoI. (2025). National Power Sector Reports and Roadmaps.

KS&K Energy & Infra Bulletins. (2025). Sector and Fiscal Updates.

Finance, Supply Chain, and Partnerships

KABIL (2025). India’s Critical Minerals MoUs.

Gravita & Lohum (2025). Urban Mining and Recycling Initiatives.

NIIF-SECI (2025). Blended Finance Pilot Documents.

Academic & Collaboration Projects

UC Berkeley–Maharashtra MoU (2024–2025). Smart Grid and Storage Integration Pilots.

India-EU TTC Summaries. (2024–2025). Regulatory Engagement on Battery Value Chain.

Consulting and Analyst Reports

McKinsey & Co. (2025). Battery Value Chain and Cost Competitiveness.

NITI Aayog (2024). India’s Battery Storage Roadmap.

Auto ET (2025). Industry Interviews and Source Data.

Comments